While an intern at M3 Design, I had the unique opportunity of owning the full development of a prototype medical device’s control system. The product is intended to clean and lubricate the internals of a client’s medical handpieces, improving tool life and sustained quality.

Medical Handpieces

To begin, I started by laying out the state machine architecture with a simple breadboarded mock-up using LEDs, switches, pushbuttons, and a display.

Initial Mock-Up

With the basic states laid out and control developed, I began integrating physical components - motors, pumps, and sensors. With these physical components, processes within each state could be defined, forming a hierarchical state machine and functional physical form.

Functional Prototype

Physical components also added another layer of complexity with debounce, power supply, overload, and motor control issues. Troubleshooting each one-by-one took time to get right, but it was an excellent way to understand the challenges in transitioning a theoretical idea or mock-up into a physical, useful device. With the physical system, we also worked on tuning the mechanical function of the device. With the mechanical design engineer, I worked to ensure that the pumps were providing the desired fluid pressure head, flowrate, and cycle duration and iteratively tuned the open-loop saturation and gain with sense resistors on the motor driver and control parameters (PWM settings).

Open-Loop Control

With the mechanical and control functions solved, user interface and experience took center-stage. Working with the team’s industrial designer, we determined workflows the user might follow, edge cases, and information to communicate to the user at each stage (alarm notifications and status/state indicators).

Sample UI Test Case

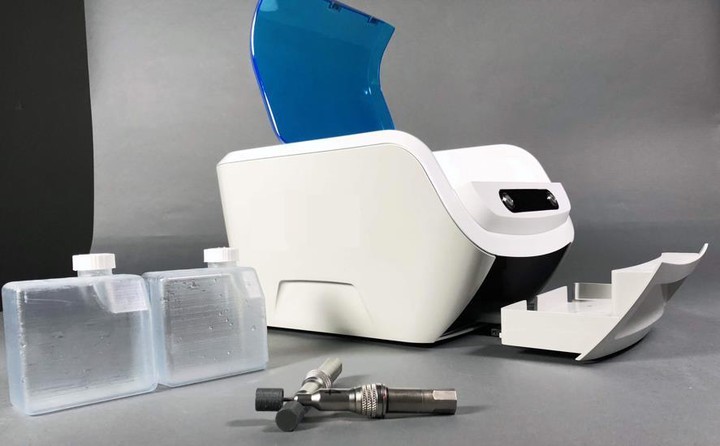

With all the pieces (controls, mechanical, UI) figured out, we finally pieced the prototype together for delivery to the client. This particular project was a great experience in negotiating needs/requirements across a cross-functional team (industrial design, mechanical engineering, and controls engineering). The final prototype was a beautiful and functional testament to everyone’s hard work and collaboration!

Final Prototype

Here’s a synopsis I presented on my experience with the project.